Selvol™ Ultiloc Product Information

The Selvol Ultiloc series comprises patented copolymers that expand the functionality of industry-trusted Selvol polyvinyl alcohol (PVOH) products. As a PVOH/PVA-based copolymer, Ultiloc combines hydrophilic film-forming properties with enhanced crosslinking and adhesion, expanding how manufacturers use PVOH in barrier and coating applications.

Compared to PVOH/PVA alone, Ultiloc copolymers offer unique characteristics:

- Better adhesion

- Improved crosslinking

- Faster dissolution

- Lower-temperature solubility

These characteristics bring efficiency and utility to many industries that already use PVOH while also enabling new innovations.

Several key patents registered by SEKISUI Specialty Chemicals support the Selvol Ultiloc series. SEKISUI has invested years of research and development into these advanced copolymers.

Download the New Copolymers Guide to learn more about the distinct properties that Ultiloc’s four grades offer.

Primary Uses for Selvol Ultiloc Copolymers

Selvol Ultiloc copolymers enhance performance across a wide range of industrial and specialty applications that traditionally rely on PVOH. Their balance of adhesion, solubility and thermal properties makes them highly adaptable to both existing formulations and new materials.

Common application areas include the following:

- Adhesives and emulsions. Improve bond strength, crosslinking efficiency and substrate compatibility.

- Coatings and flexible packaging. Enable better film formation, moisture resistance and low-temperature processability.

- Construction materials. Strengthen formulations and promote cohesive performance in cementitious systems.

- Textiles and paper. Support improved surface finish, film flexibility and rapid dissolution.

- Inks, ceramics and personal care. Contribute rheology control, dispersion stability and binder performance.

Each grade delivers specific properties. Some offer cold-water solubility; others provide enhanced adhesion on low-energy surfaces. Together, they extend the capabilities of standard Selvol PVOH polymers.

Selvol Ultiloc 5003, the first in the series, demonstrates these advantages through its reactivity, adhesion strength and crosslinking behavior.

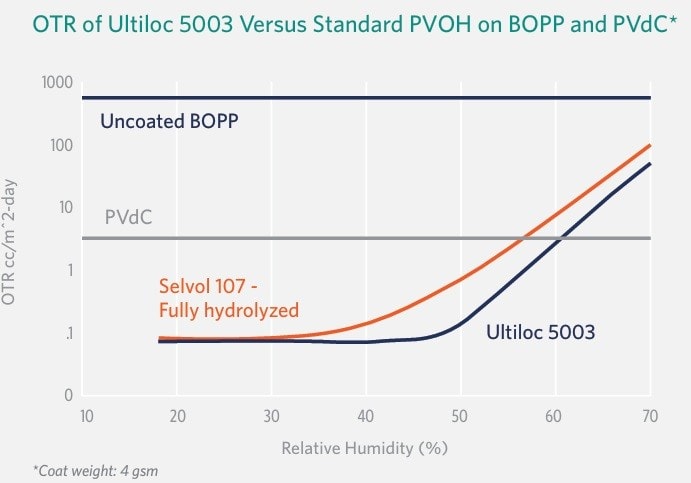

Ultiloc 5003 demonstrates better OTR results on BOPP and PVdC under relative humidity.

Selvol Ultiloc 5003

SEKISUI’s Ultiloc 5003 is among the most widely used products in the Ultiloc series. It demonstrates superior adhesion to many substrates, including corona-treated BOPP and BOPET.

Industries often use it in flexible packaging films, where it helps reduce layer count and total gauge weight. Ultiloc 5003 also provides excellent gas-barrier performance, allowing it to replace traditional barrier materials such as PVdC and EVOH.

Laboratory data shows Ultiloc 5003 delivers significantly lower oxygen transmission rates (OTR) than standard PVOH. It maintains strong barrier performance even at up to 65% relative humidity.

Read about Ultiloc 5003 for flexible packaging.

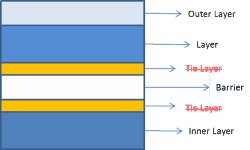

Ultiloc enables stronger, more flexible barrier coatings with fewer layers.

Key Advantages of Selvol Ultiloc 5003

Ultiloc 5003 combines performance, process efficiency and sustainability advantages in one multifunctional copolymer:

- Higher reactivity, enabling improved crosslinking and stronger post-reaction performance.

- Excellent adhesion to plastics, glass, metals, wood and low-energy surfaces like BOPP and BOPET.

- Effective additive for improving adhesion and cohesion in emulsion-based adhesives and tie layers.

- Exceptional gas-barrier performance at low to moderate humidity, reducing oxygen transmission.

- Lower-temperature solubility with fast dissolution for efficient processing.

- Cationic at neutral or acidic pH, compatible with diverse formulations.

- High surface energy, ideal for vapor metallization and high-barrier coatings.

- Environmentally friendly, low-VOC and recyclable for sustainable mono-material and biopolymer films.

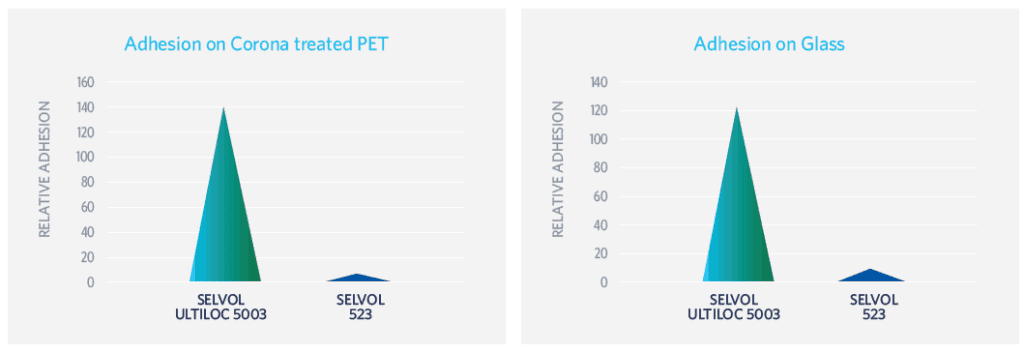

Ultiloc demonstrates greater adhesion on Corona-treated PET and on glass.

Ultiloc 5003: Industries and Applications

Manufacturers widely use Selvol Ultiloc 5003 in flexible packaging, adhesives and coatings where barrier strength and adhesion are critical. It performs especially well in food packaging films, laminate structures and mono-material applications replacing PVdC or EVOH.

Beyond packaging, it supports construction materials, industrial coatings, textile finishes and paper treatments that benefit from its rapid dissolution and film flexibility. Its compatibility with both traditional and biopolymer substrates makes it valuable for lightweight, recyclable and sustainable product design.

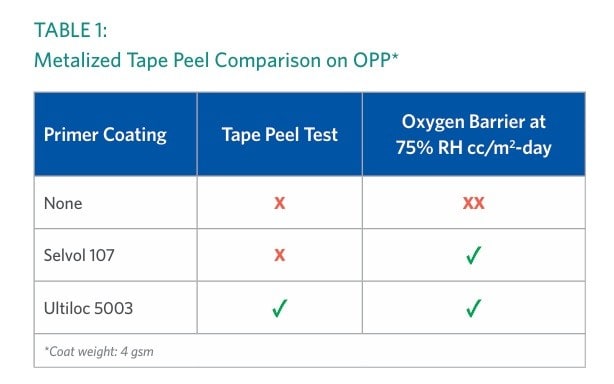

Ultiloc 5003 shows improved adhesion in a metalized tape peel comparison.

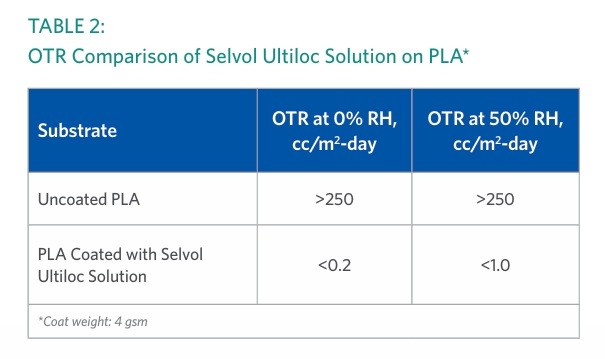

Ultiloc 5003-coated PLA exhibits greatly reduced oxygen transmission rate (OTR).

Ultimately, these characteristics lend Selvol Ultiloc 5003 to other applications in which adhesion and crosslinking are crucial.

Contact SEKISUI for Ultiloc PVOH Grades

Contact SEKISUI Specialty Chemicals for more information about Selvol Ultiloc PVOH, or request samples to try grades.

Selvol Ultiloc copolymers represent next-generation PVOH technology, combining strong adhesion, fast dissolution and reliable barrier protection across industries.