Films and Packing Applications

Our Selvol™ polyvinyl alcohol (PVOH) and Ultiloc resins offer unique attributes for films and packing:

- Possible water solubility

- Possible biodegradability and compostability

- Oxygen and other gas and odor barrier properties

- Solvent, oil and grease resistance

- Inherently antistatic properties

- Innocuous and environmentally friendly properties

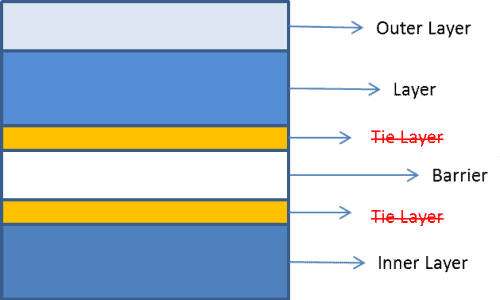

Selvol™ Ultiloc barrier resins have verified gas barrier performance with higher adhesion properties, making them an excellent fit for a variety of flexible films and packing applications. For example, Selvol Ultiloc barrier resins offer these distinct benefits:

- Thinner films with lower gauge weights

- Potential for fewer layers in laminate structures, without adhesive tie layers

- Better film clarity

- Potential replacement of other barrier technologies

Selvol Ultiloc 5003 offers these characteristics:

- Superior oxygen transmission rate (OTR)

- Zero chlorine

- Higher reactivity for greater crosslinking characteristics to improve moisture vapor transmission rate (MVTR)

- Excellent adhesion and the ability to be coated directly onto corona-treated BOPP and BOPET

- This indicates adhesive tie layers are unnecessary, and it produces thinner, simpler laminate films.

- Ultra-clear coating production

- Heat-sealable attributes

These qualities make it an excellent choice for films and packing applications.

Please contact us for more information, or request a sample.