Packaging plays a critical role across industries like pharmaceuticals, electronics and food.

In the food industry, packaging isn’t just functional. It’s essential for protecting quality, extending shelf life and preserving sensory attributes like taste and smell. It also delivers important nutritional information to consumers.

Fifty years ago, manufacturers stored perishable foods like meat, cheese and vegetables in glass or metal due to their durability and shelf-life benefits. Even beverages like soda exclusively used glass packaging. However, today’s global food systems, shifting consumer preferences and new regulations have all contributed to major changes in food-grade plastic packaging.

Plastic Packaging Today: Safe and Versatile but Imperfect

Most flexible food packaging today relies on petroleum-based plastics. These include the following:

- Polyethylene terephthalate (PET)

- Low- and high-density polyethylene (LDPE and HDPE)

- Polypropylene (PP)

- Polyvinyl chloride (PVC)

- Polystyrene (PS)

Plastic containers offer considerable benefits. For example, they don’t shatter like glass, and they’re lighter and often safer than metal. They’re easily moldable and printable, making them attractive surfaces for food branding.

Nonetheless, flexible packaging materials have limitations, especially in barrier performance and environmental sustainability.

The Evolution of Flexible Food Packaging Films

The first generation of plastic food packaging, such as potato chip bags, offered limited shelf life. Chips quickly became stale. Even today, certain products last longer in metal than in plastic, and extreme processing (like high-heat retort) still favors metal containers.

Flexible barrier packaging has come a long way. Manufacturers use today’s flexible packaging films even for demanding applications like retort pouches or aromatic food packaging. Food manufacturers now demand packaging that reduces costs, improves shelf life, simplifies processing and appeals to consumers.

Furthermore, packaging must do all this while improving sustainability.

SEKISUI’s Selvol™ Ultiloc copolymers meet this challenge.

Meet Selvol Ultiloc: Next-Generation Food-Grade Copolymers

Selvol Ultiloc is a series of patented copolymers that build on the proven performance of Selvol polyvinyl alcohol (PVOH). Designed specifically for flexible packaging film and extrusion applications, Ultiloc retains key PVOH benefits while enhancing functionality.

Compared to conventional PVOH polymers, Selvol Ultiloc offers the following:

- Stronger adhesion

- Faster dissolution and lower-temperature solubility

- Improved crosslinking and stability

- Greater flexibility for new and existing uses

These enhancements make Ultiloc suitable for a range of flexible packaging adhesives and laminate structures.

Why Food-Grade Flexible Packaging Uses So Many Layers

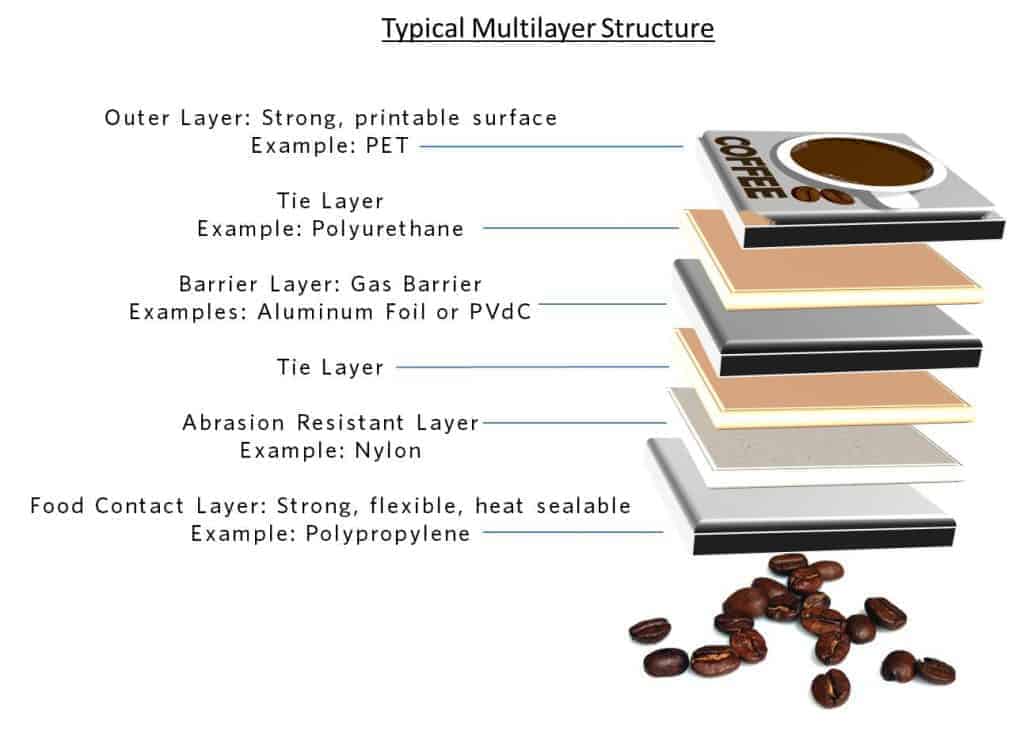

Plastic is more permeable than glass or metal, especially to oxygen, which accelerates food spoilage. To address this, flexible plastic packaging often uses multiple barrier layers. Each layer in a flexible packaging laminate has a specific role:

- Outer layer (e.g., printability or aesthetics)

- Tie layer (bonding dissimilar materials)

- Barrier layer (oxygen/moisture protection)

- Abrasion-resistant layer

- Food-contact layer (meets food safety standards)

When combined, these layers create flexible packaging films with performance approaching that of metal or glass. They often do so at the cost of complexity, recyclability and sustainability.

An illustration of this typical multilayer structure is below.

The Challenge with Traditional Barrier Layers

Aluminum foil, commonly found in small food packaging and retort pouches, delivers excellent gas barrier properties. Manufacturers must apply it in thick layers (>25 µm), which adds cost and weight. It’s also not microwave-safe and poses recyclability issues.

Other barrier materials like polyvinylidene chloride (PVdC) offer strong gas protection. However, manufacturers are phasing them out due to environmental concerns.

A Smarter Alternative: Ultiloc Copolymers in Laminates and Films

Selvol Ultiloc copolymers provide a sustainable, food-safe alternative to aluminum and PVdC. They are environmentally benign and offer excellent oxygen barrier properties even at low humidity.

Key benefits for flexible packaging sustainability include the following:

- Has a surface energy >55 dynes/cm, enabling strong bonding

- Serves as a nucleation layer for metal vapor deposition

- Reduces or eliminates need for tie layers

- Is compatible with high-performance laminates in food packaging

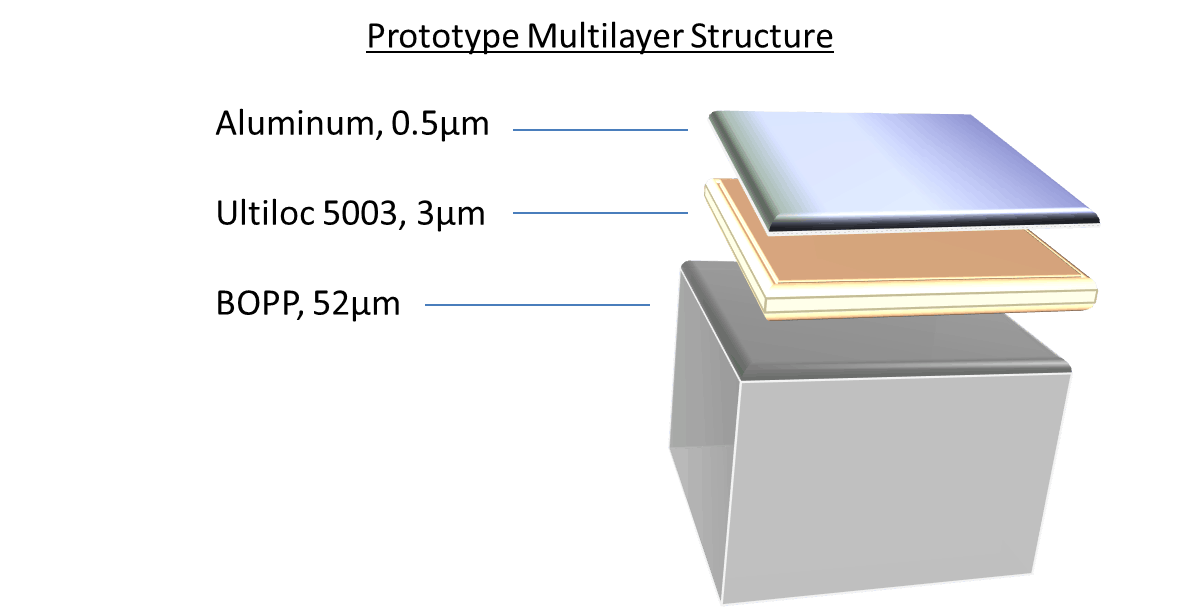

A recent prototype used Selvol Ultiloc 5003 in a multilayer structure. With a thin aluminum vapor layer, the barrier performance remained strong even at high humidity levels.

To demonstrate this, SEKISUI recently produced a prototype multilayer film using Selvol Ultiloc 5003, as shown below.

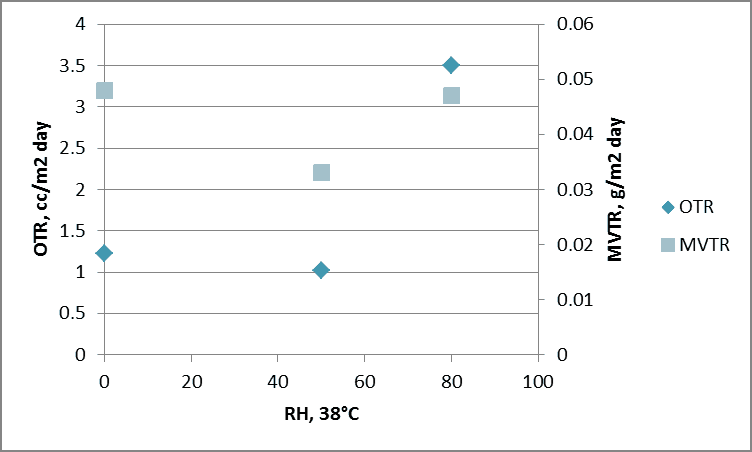

Engineers coated the prototype film with a thin layer of aluminum. The barrier properties were good even at high humidity with such a thin metal layer, as shown in the plot below.

The Future: Fewer Layers, Better Performance

Ultiloc copolymers demonstrate the potential for lighter, transparent flexible packaging films that maintain critical barrier properties with fewer layers and converting steps. The results are outstanding:

- Lower packaging and shipping costs

- Reduced environmental impact

- Improved flexible packaging sustainability

- Maintained food safety and shelf life

Contact SEKISUI for Better Packaging Options

Contact a SEKISUI polymers specialist to learn more about Selvol Ultiloc, or request samples to try it for film packaging applications.

Reach out to the SEKISUI Technical Service Team for a free consultation.