Welcome TAPPI member!

Sekisui Specialty Chemicals offers a complete line of polyvinyl alcohol resins for paper applications. Our manufacturing facilities in Calvert City, Ky., Pasadena, Texas, and Tarragona, Spain, employ advanced computer-controlled production technology, providing polyvinyl alcohol of the highest quality. All plants are ISO 9002 certified.

As part of our commitment to the paper industry, Sekisui Specialty Chemicals maintains a fully staffed paper applications laboratory in Houston, Texas. The lab is equipped with a variety of state-of-the-art analytical instruments to support applications and customers in the paper market.

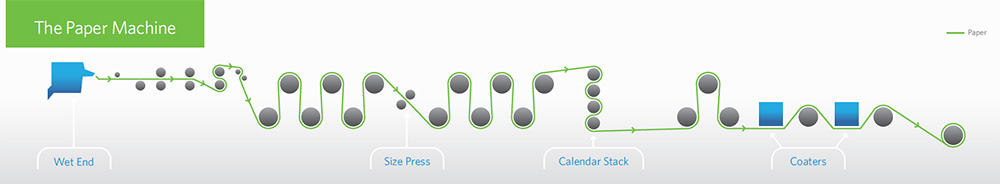

Paper Machine

Selvol At the Coater

Cobinder

Because of its superior strength, coatings formulated with Selvol polyvinyl alcohol can achieve a significant reduction in total binder level. This may provide for substantial cost savings while providing a significant improvement in brightness, gloss and opacity. The water retention properties of polyvinyl alcohol also allow coatings to be formulated with a reduced or zero level of hydrocolloid. Unlike some natural cobinders, polyvinyl alcohol does not require use of a base like ammonia to be solubilized.

Ink Jet Dyes

Polyvinyl alcohol is the preferred binder for ink jet coatings utilizing silica pigments. It provides superior binding strength and improved ink jet print quality versus typical latex binders. Polyvinyl alcohol is a hydrophilic polymer which acts in concert with the silica pigment to quickly absorb the water-based ink into the coating layer, thus minimizing wicking, mottle and bleed.

Optical Brightner Carrier

Polyvinyl alcohol is recognized as the best carrier for fluorescent dyes. The addition of 0.5-2.0 parts (dry) polyvinyl alcohol per 100 parts pigment can boost brightness an additional 4+ units. Such improvements are significant for high 80s/low 90s brightness papers. Polyvinyl alcohol also provides superior binding strength and good water retention properties, enabling reductions in latex and hydrocolloid levels. Selvol™ Polyvinyl Alcohol 203S, a fine grind version of Selvol™ Polyvinyl Alcohol 203 polyvinyl alcohol (99% of the particles pass through an 80 mesh screen), can be used as a noncook carrier by adding it directly to a pigment dispersion or a pigmented formulation while under high shear agitation for a minimum of 15 minutes.

The concept of using Selvol™ Polyvinyl Alcohol 203S in coating color formulations as a “non-cook” product, either as a pigment binder or as a carrier for optical brighteners is described in U.S. Patent 5,057,570 assigned to Sekisui Specialty Chemicals.

Selvol At the Size Press

Clear Sizing

Selvol polyvinyl alcohol finds use at the size press as a clear size to impart surface strength and barrier properties. In this capacity, it is often used to upgrade the performance of starch. Polyvinyl alcohol performs well at this function because it is much stronger and much more resistant to oils, greases, waxes and organic solvents than other surface sizing agents.

Pigmented Surface Sizing

Because of its superior strength, polyvinyl alcohol can be formulated at much lower levels than other binders, thus optimizing the brightness and opacity effects of the pigment system.

Ink Jet Papers

Polyvinyl alcohol is the preferred binder for ink jet size press coating formulations using silica pigments. Its superior binding strength controls the dusting which may occur with starch. Polyvinyl alcohol is a hydrophilic polymer which acts in concert with the silica pigment to quickly absorb the water-based ink into the coating layer, thus minimizing wicking, mottle and bleeding.

Optical Brightener Carrier

Compared with starch, polyvinyl alcohol delivers 2.0-2.5 more UV brightness units (or conversely, a reduction in the level of expensive fluorescent dye at equal brightness). This greater efficiency may allow the reduction or elimination of fluorescent dyes at the wet end.

Oil and Grease Resistance

Polyvinyl alcohol exhibits excellent barrier properties to oils, greases, waxes and solvents. It is used alone or with starch to meet Vanceometer, Turpentine, K&N ink holdout and other specifications. Polyvinyl alcohol is also a very effective carrier for fluorochemicals. Blends of polyvinyl alcohol and fluorochemicals achieve high 3M Kit Ratings at a cost much lower than with the use of a fluorochemical by itself.

Hydrophobicity

Surface applications of polyvinyl alcohol and alkyl ketene dimer (AKD) blends demonstrate outstanding improvements in Cobb and Hercules Sizing (HST) values on both acid and alkaline papers, with little or no loss in size values upon aging. Unlike starch, a surface application of polyvinyl alcohol does not degrade the internal sizing effect of a wet end additive like AKD or ASA.

Plybond Adhesion

The superior strength of polyvinyl alcohol provides an effective means of achieving plybond adhesion on multi-ply paperboard.

Selvol At the Wet End

Stickies Control

Selvol polyvinyl alcohol is used to control the deposition of stickies associated with the use of secondary fiber. The polyvinyl alcohol encapsulates the stickies and forms a multilayer shield that effectively covers the surface, rendering it nontacky. Features of this technology may be covered by U.S. Patent 4,886,575 assigned to Betz Laboratories, Inc.

Polyvinyl alcohol may also be effective in controlling pitch deposition in Kraft, acid sulfite and ground wood papermaking systems. Features of this technology may be covered by U.S. Patent 4,871,424 also assigned to Betz Laboratories, Inc.

* These applications may be subject to certain U.S. patents and equivalents issued in other countries. No license is granted with the purchase of Selvol™ Polyvinyl Alcohol. Please contact your Sekisui Specialty Chemicals sales representative for additional information.