The packaging industry is seeing a significant trend toward paperization: substituting traditional plastic-based materials with paper- and fiber-based alternatives. Paperization is gaining traction for its potential to reduce packaging waste and minimize environmental impact.

Polyvinyl alcohol (PVOH) is an excellent enabler in this trend, lending crucial performance properties to paper substrates. SEKISUI Specialty Chemicals offers both trusted Selvol™ PVOH and new Selvol PC grades. These water-based coatings deliver oxygen, oil and grease resistance while maintaining recyclability.

Read the Selvol product brochure.

What Is Paperization?

Paperization refers to the growing movement within the packaging sector to replace plastic packaging with paper- and fiber-based alternatives. This spans applications from consumer goods packaging to industrial materials.

Overall, it reflects a growing shift in how manufacturers approach packaging materials and performance. The approach involves not only substituting paper for plastic but also finding formulations that lend paper-based materials certain characteristics:

- Oil and grease resistance (OGR)

- Oxygen barrier properties

- Strength

- Printability

- Versatility in end uses

- Recyclability

The eco-friendly aspect of paperization is among its most powerful drivers.

Read more about Selvol for paper and paperboard applications.

Paperization Industry Insights: Drivers

Packaging made from renewable fibers offers compelling environmental advantages, making it an increasingly popular option. Eco-focused factors are also pushing paperization into the global mainstream:

- Greater environmental awareness

- Regulatory measures

- Rising preference for green solutions

As interest in sustainable practices grows, consumers and industries alike explore new ways to reduce environmental impact. Paper-based solutions appeal to many consumers because of their recyclability, renewability and potential to reduce landfill burden.

Two key factors accelerate this momentum:

- Pollution. Plastic pollution is a growing environmental concern, driving demand for packaging alternatives. Manufacturers respond by exploring paper-based materials and reimagining more eco-friendly plastics.

- Markets. Consumers are more willing to purchase products from companies using sustainable packaging, encouraging innovation across industries.

Meanwhile, manufacturers in sectors working with plastics are proactive in improving performance and sustainability. PVOH plays a role in this evolution, enhancing plastic- and paper-based packaging with excellent barrier properties while supporting environmental goals.

However, achieving the performance characteristics necessary in paper packaging can be challenging. PVOH bridges this performance gap while supporting sustainability.

The packaging industry is undergoing changes to decrease waste and increase recyclability.

The Case for Paperization in Packaging

Packaging innovation is evolving in response to global sustainability goals. Each year, plastic production generates roughly 400 million tonnes of plastic waste. Much waste comes from high-volume applications like frozen meals and fast-food packaging.

While these materials have been vital in preserving product quality and convenience, they decompose slowly. Some food packaging has contained PFAS, now under increasing regulatory review. This has prompted industries to explore lower-impact alternatives.

Paperization offers a path forward, supporting recyclability and biodegradability through fiber-based packaging made from recycled or sustainably sourced materials. Single-use paper products generally biodegrade more easily and integrate into recycling systems.

The movement is not simply about switching one material for another. It represents a broader change in mindset and a push toward innovation in paper and plastic.

How OGR Plays a Large Part in Paperization

OGR measures how effectively a material prevents oil and grease from penetrating. Plastics have long been a food industry standby due to their OGR; approximately 50% of all packaging material is single-use. However, robust OGR paper can be difficult to manufacture.

Selvol PVOH offers a solution by acting as a barrier layer within the packaging composition. It forms a continuous film that provides reliable OGR, preventing penetration through layered substrates. This barrier is essential for maintaining freshness and quality while preventing contamination.

Formulated without PFAS, EVOH or solvents, Selvol PC grades meet global food-contact regulations. They bond directly to cellulosic substrates without the need for primers or tie layers. This makes them a safe, sustainable choice for plastic-alternative paper packaging and barrier coatings that balance compliance, performance and recyclability.

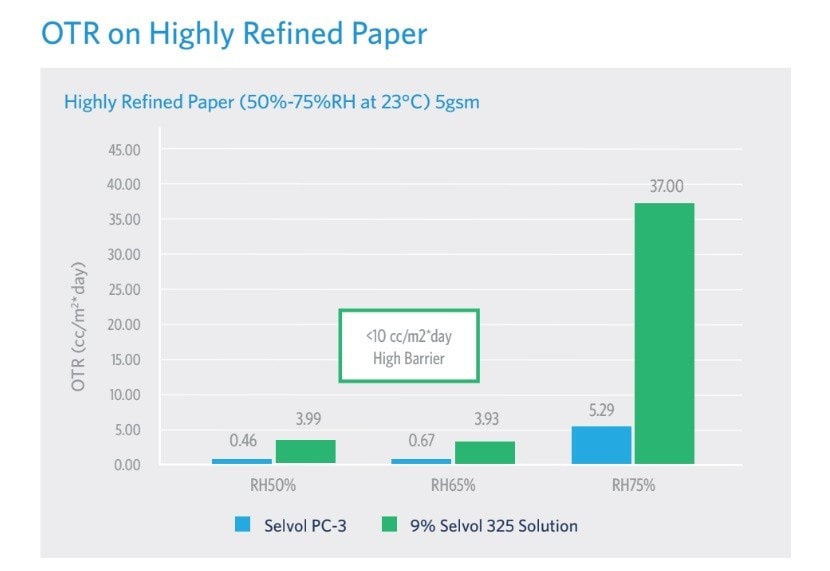

Selvol PC-3 achieves an OTR below 10 cc/m²·day on highly refined paper, outperforming standard PVOH across humidity levels.

Why PVOH Holds Promise for Paperization

Selvol PVOH’s innate properties contribute substantially to paper- and fiber-based packaging:

- Film-forming ability. PVOH forms a cohesive, pinhole-free film that creates an effective OGR barrier, maintaining packaging integrity and preventing leakage.

- Biodegradability. Water-soluble PVOH supports recyclability and biodegradability, helping formulators produce environmentally responsible OGR paper products.

- Customization. Available in multiple grades, PVOH allows manufacturers to tailor barrier performance for light to heavy-duty applications.

- Crosslinkability. PVOH’s hydroxyl (OH) groups allow for strong crosslinking, enhancing water resistance while maintaining durability and flexibility.

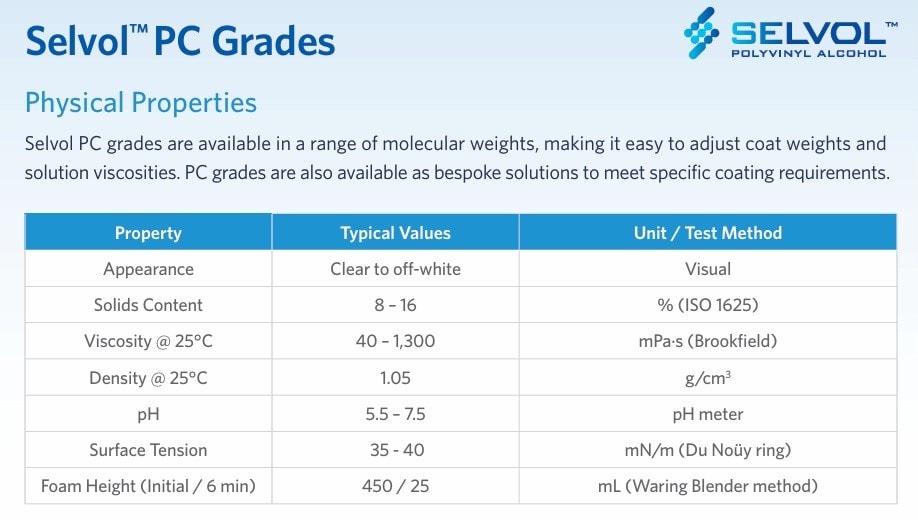

Selvol PC grades contain 8%–16% solids and reach viscosities up to 1,300 mPa·s. They coat smoothly across gravure, rod and slot-die systems, while low foam levels ensure uniform surfaces at production speed. This makes them an ideal fit for plastic-alternative paper and fiber packaging lines requiring consistency and efficiency.

Selvol PC grades offer customizable characteristics, providing coatings ideal for recyclable paper and packaging applications.

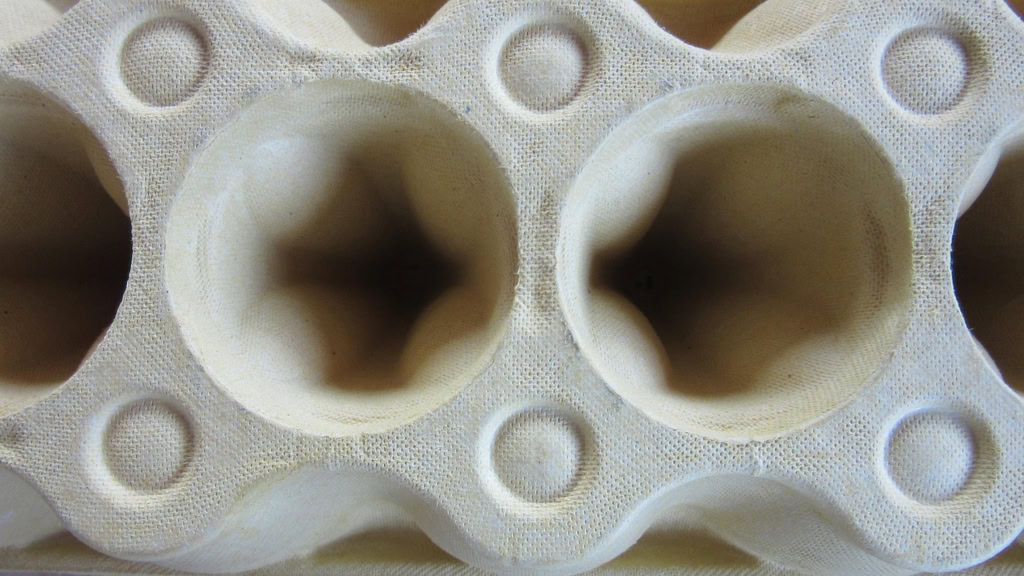

The Molded Fiber Industry and PVOH: A Perfect Match

PVOH is also making strides in the molded fiber product industry. Formed from recycled paper or plant fiber slurry, molded fiber is gaining popularity as a plastic-alternative packaging material.

Molded fiber products such as egg cartons and food trays benefit notably from PVOH’s film-forming and OGR properties. PVOH coatings strengthen fiber networks, improve surface smoothness and protect against moisture and grease.

Selvol PVOH and Selvol PC enhance molded fiber packaging in crucial ways:

- Food trays. Improved OGR prevents leaks and maintains structural integrity.

- Drink holders. Strengthened fibers resist deformation from moisture and weight.

- Frozen meal packaging. Enhanced resistance to freezer burn and moisture extends shelf life.

- Egg cartons. PVOH coatings bolster cushioning and reduce breakage during transport.

With PVOH, paper-based formats can meet demanding performance needs while advancing sustainability objectives. This applies from thin single-use wraps to durable molded fiber containers.

Common molded fiber products include egg cartons and fast-food containers. (via Pixabay)

The Future of Paperization: Selvol PVOH

Selvol PVOH continues to outperform other adhesives in paper-based packaging and molded fiber manufacturing. Selvol PC grades extend this capability with water-based, ready-to-apply barrier coatings. Together, they create greener packaging that withstands moisture, transport, weight and temperature changes.

Paperization’s future extends beyond food and beverage packaging. Retail, personal care, healthcare, industrial and textile sectors are adopting recyclable, fiber-based formats as demand grows.

Emerging innovations driving paperization include the following:

- Advanced, compostable barrier coatings

- Lightweight, sustainably sourced fiber blends

- High circularity

- Easily printable paper-based packaging

Selvol PC grades suit plastic-alternative packaging such as snack containers, bakery wraps and molded paperboard. These coatings deliver strong barrier performance against oxygen and mineral-oil migration and provide excellent OGR on paper surfaces. Grades are available worldwide as ready-to-use aqueous solutions or dry powders to support stronger, greener packaging innovations.

The shift toward paperization continues to create long-term value for manufacturers while advancing meaningful environmental progress.

Selvol has proprietary ready-made solutions available.

Contact SEKISUI Specialty Chemicals for Selvol PVOH

SEKISUI Specialty Chemicals is committed to sustainable innovation through its product family. The paperization trend continues to grow, and Selvol PVOH and Selvol PC contribute critical qualities to paper and fiber packaging.

Contact SEKISUI to learn more about Selvol PVOH grades, or request samples to try them firsthand.

Reach the SEKISUI Technical Service Team for one-on-one assistance and outstanding customer support.