Selvol Ultiloc 5003

for Enhanced Barrier in Flexible Packaging

SEKISUI Specialty Chemicals is pleased to introduce Selvol Ultiloc 5003. As part of the Ultiloc family, it expands on the proven performance of Selvol polyvinyl alcohol (PVOH/PVA).

Ultiloc 5003 integrates enhanced reactivity, adhesion and film formation into one advanced PVOH copolymer for modern coatings and packaging.

Request an Ultiloc 5003 Brochure

Enter your name and email to receive a brochure with the latest test data about Selvol Ultiloc 5003.

Key Characteristics

Ultiloc 5003 combines multifunctional chemical traits that boost performance across coatings, films and related formulations.

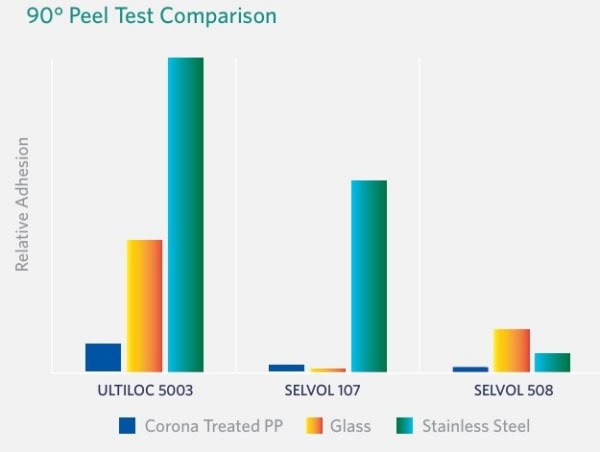

Ultiloc 5003 demonstrates superior multi-substrate adhesion compared to Selvol 107 and Selvol 508 in 90° peel tests

Typical Properties and Solution Preparation Guidelines

Learning Ultiloc 5003’s core properties helps you prepare stable, consistent solutions for coatings, films and other formulations. Use these guidelines to support predictable viscosity, film quality and coating behavior.

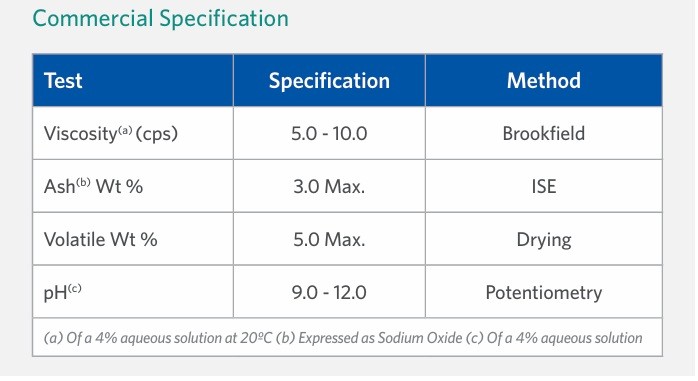

Commercial and Analytical Properties (Solution Basis)

These solution-based properties define Ultiloc 5003’s behavior in solution and during application:

- Viscosity (4% at 20 °C): 5.0–10.0 cPs

- Ash (wt%): ≤ 3.0 (as Na₂O)

- Volatile (wt%): ≤ 5.0

- pH (4%): 9.0–12.0

Recommended Solution Range

Ultiloc 5003 performs well in 10–15% by-weight solutions. This range balances viscosity and supports smooth, uniform film formation.

These concentrations provide predictable handling during mixing and application. They also support stable viscosity profiles across typical coating and drying conditions.

Preparation Steps for Stable Coatings

Follow these steps to prepare Ultiloc 5003 solutions for consistent performance:

- Charge room-temperature water to a vessel with active mixing.

- Begin agitation until the surface moves vigorously.

- Add Ultiloc 5003 gradually, then heat to 85–90 °C.

- Hold at temperature for about 30 minutes to fully dissolve.

- Optional: Add 10–20% IPA or ethanol to aid coating low-energy substrates and reduce foaming.

A biocide is not required for storage over 24 hours. Premade Ultiloc 5003 solutions are available for fast preparation.